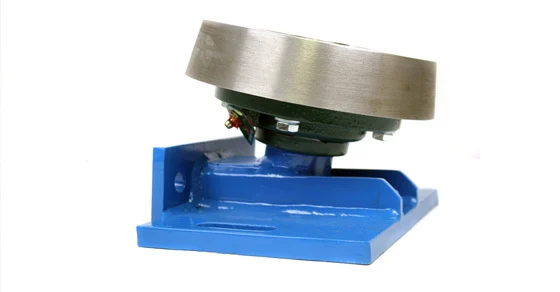

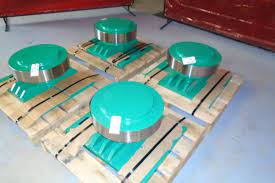

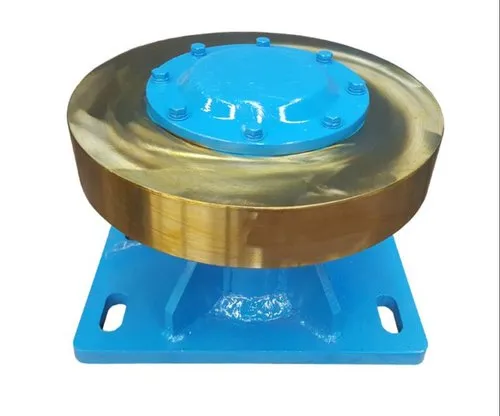

Axial Thrust Roller (Riding Roller) Assembly

Axial Thrust Roller (Riding Roller) Assembly

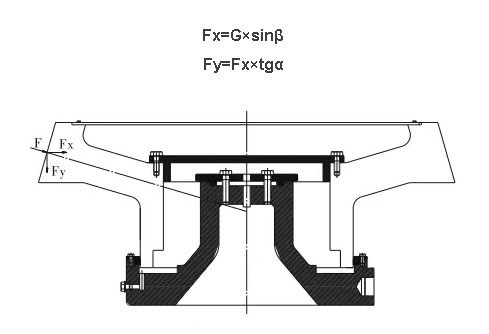

Indian Premium Gears make Axial Thrust Roller Assembly is a component in rotary kilns and similar machinery that counteracts and supports the axial load generated by the weight of the rotating drum. This assembly includes a roller mounted on bearings and positioned to resist the axial forces, ensuring stable and controlled axial movement of the rotary equipment. The assembly plays a key role in maintaining proper kiln alignment and preventing issues such as misalignment, excessive wear, and uneven loading during operation.

Major Specification:

| Material |

| Max. Diameter |

| Weight |

| Heat Treatment |

| Other Specification |

| Quality |

| Application |

| Assembly |

| Graded Alloy steel & Carbon steel Etc.. |

| 1500 mm |

| 0.5-20 MT |

| Annealing, normalizing, quenching, or tempering |

| Customised |

| NDT, UT, MPI, DPT |

| Rotary kiln, rotary dryer, etc |

| Complete assembly with shaft and bearing fitted |

Key Features of Axial Thrust Roller Assembly:

- Precise Alignment

- Robust Bearing Technology

- High-Quality Alloy Construction

- Axial Load Distribution

- Efficient Lubrication Systems

- Adjustment Mechanisms

- Thermal Resistance

- Customization Options

Advantages of Axial Thrust Roller Assembly:

- Stable Axial Support

- Reduced Wear and Tear

- Enhanced Kiln Alignment

- Extended Equipment Lifespan

- Smooth Operation

- Minimized Downtime

- Improved Safety

Axial Thrust Roller (Riding Roller) Assembly