Girth Gears

Girth Gears

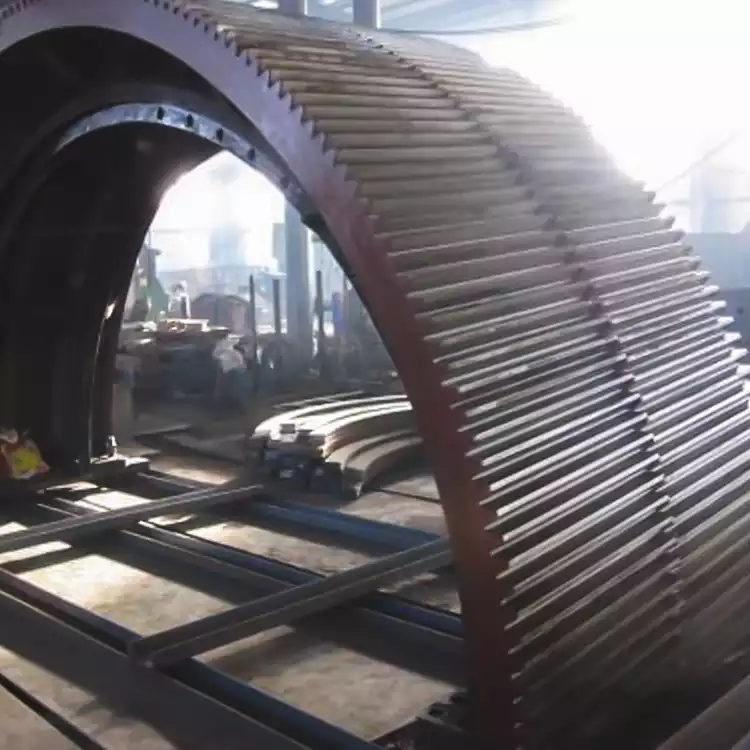

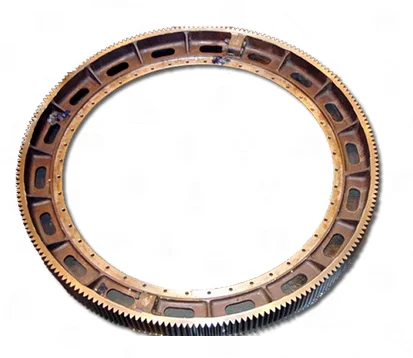

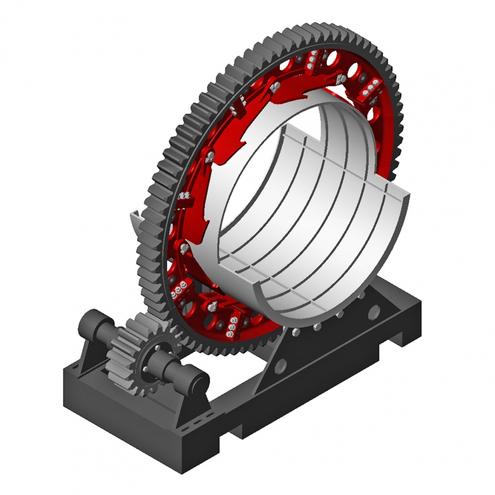

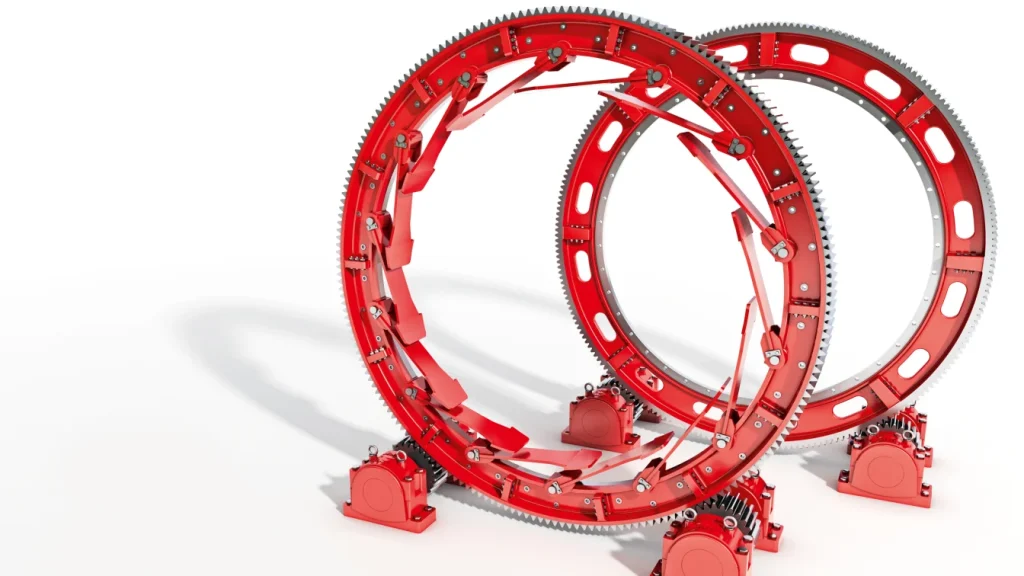

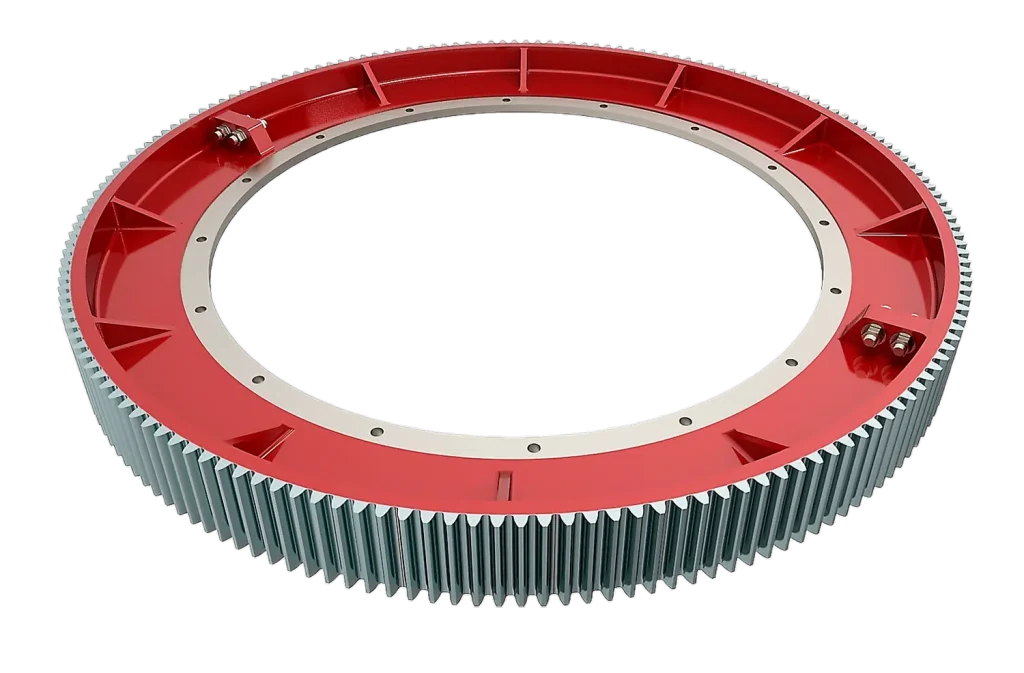

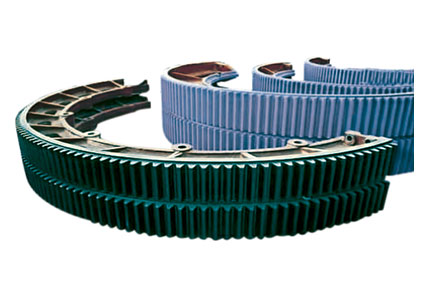

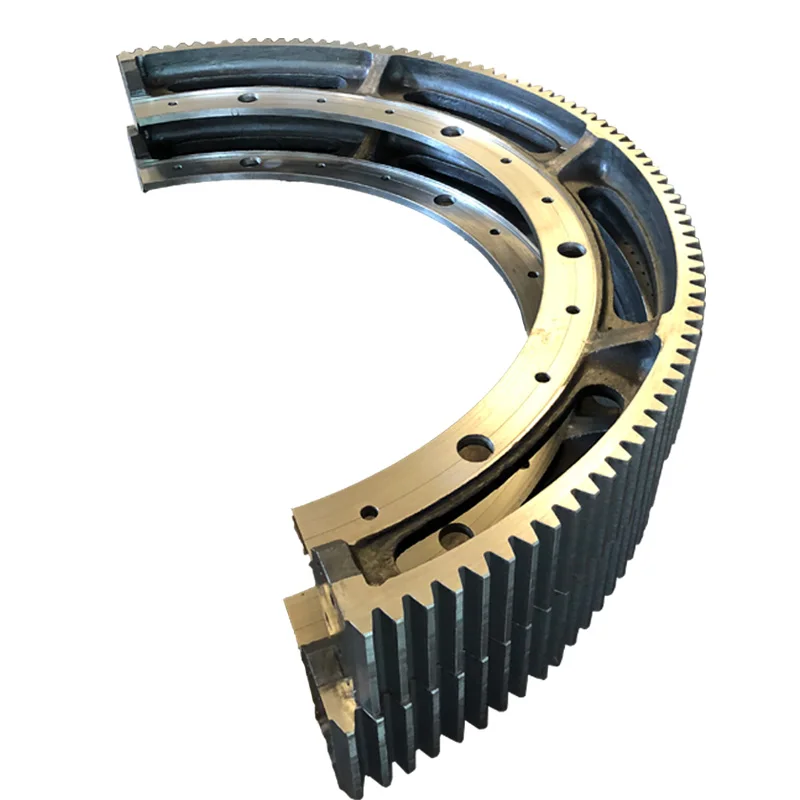

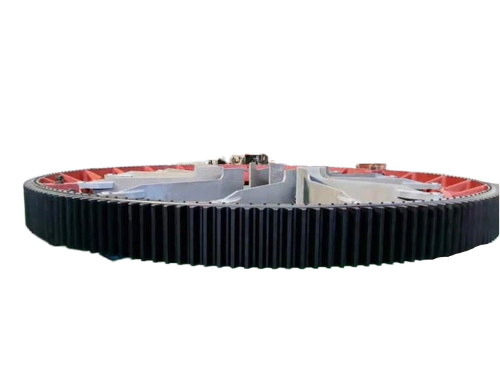

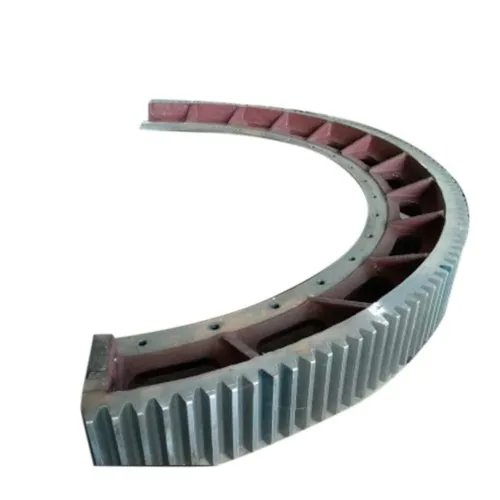

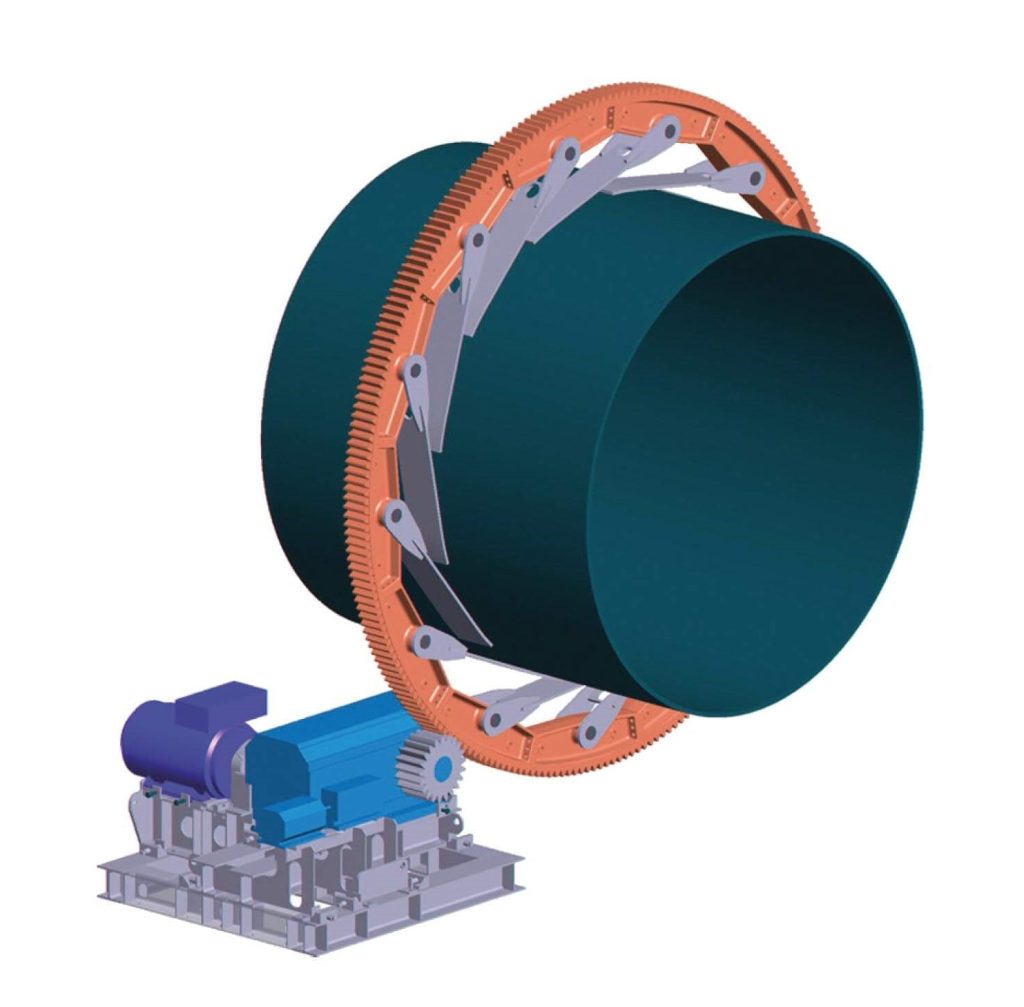

Many critical industries adopts girth gears for machinery design, such as mining , cement manufacturing, it is used to form the primary rotational drive system of ball mills, rotary mills and kiln, etc. It is required to be with high strength with long service life, it must have high quality for downtime would cost a lot in mining production.

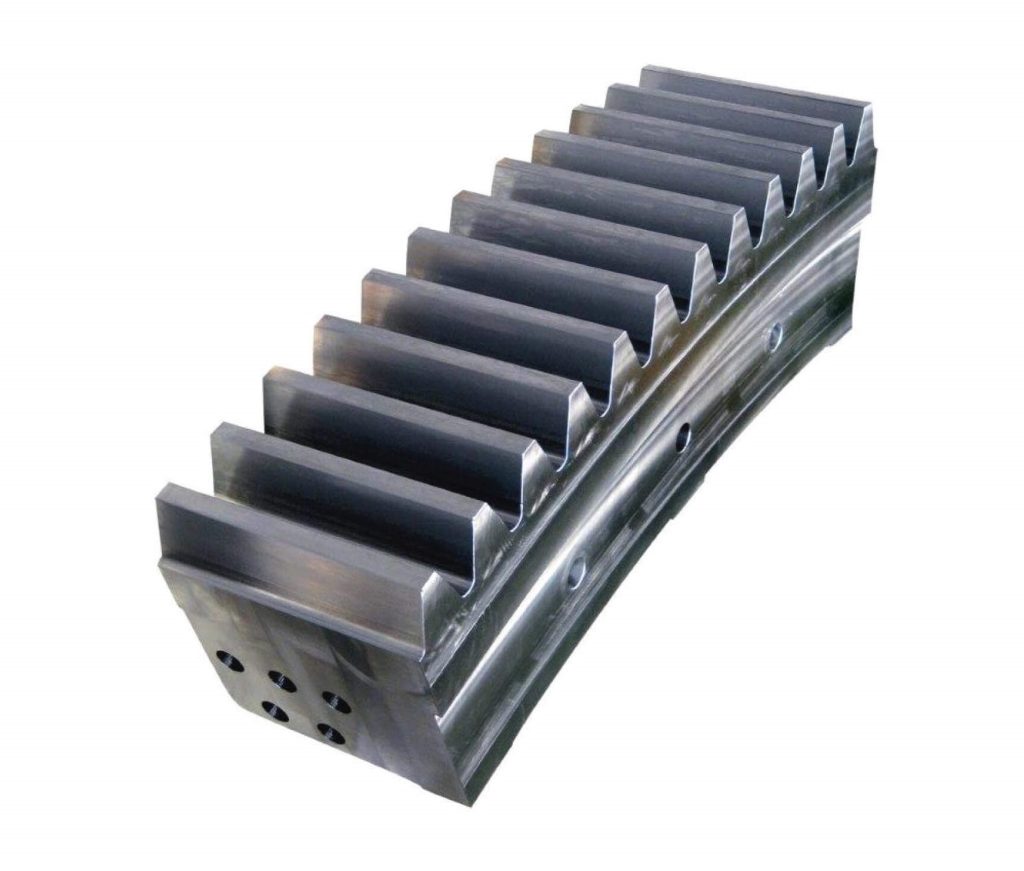

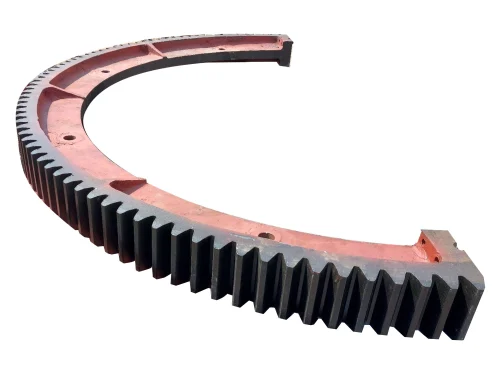

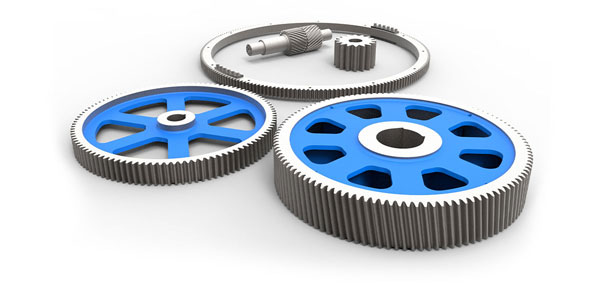

Girth gear is also known as gear wheel, forged steel formed shafted pinions teeth, it is produced through harden or case carburised to meet the requirement of high cutting quality and surface finish requirements of application. it is a large ring gear installed on the outside of main body of ball mills, Rotary mills, cement mill. Until now, it has developed into many types for different heavy equipments, such as mills, kilns, dryers, coolers, scrubbers.

Girth Gear Manufacture Process:

1.Simulation & Analysis

2.Wood Pattern

3.Sand Mould

4.Smelting

5.Molten Steel Test

6.Pouring

7.Sand Cleaning

8.Heat Treatment

9.Finishing

10.Machining

11.Non Destructive Testing

12.Package

Girth Gears